- The Whitworth quick return mechanism is used in slotting and shaper machine. The most important factor consider with this is time. This requires more time than the return stroke and there is cutting in the forward stroke.

- The precision slotter machines are also used for general purpose work and are usually fitted with Whitworth quick return mechanism. Slotter Size The size of a slotter machine like that of a shaper is specified by the maximum length of stroke of the ram, expressed in mm.

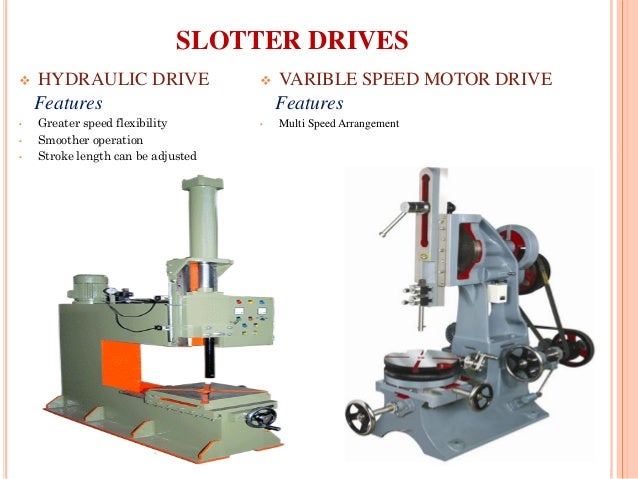

Slotting Machine

Product Features:

This machine is suitable for single-piece or small-batch production with cutting various plane, formed surface and key way etc. The main transmission mechanism is used for converting the rotating motion of the crank gear into reciprocating motion of rain. Longitudinal, cross and rotary for worktable feeding are automatically or manually. Worktable can automatically stop running by safety device in case of fault. The worktable can index as per the workpiece requirement. The machine is accompanied with an electron magnetic automatic tool holder and a tool bar. The tool holder is used for outer slotting and the tool bar for inner slotting and for slotting the key-way.

Slotting machine mechanism & slotting machine mechanism online Wholesalers - choose slotting machine mechanism from 636 list of China slotting machine mechanism Manufacturers.

Technical Specifications

ITEM | UNIT | B5032(D) | B5040(D) |

Max. slotting length | mm | 320 | 400 |

Max. dimension of work piece(L*W) | mm | 600*320 | 620*320 |

Max. weight of work piece | Kg | 500 | |

Max. cutting force | N | 7500 | |

Number of ram reciprocation (per min.) | 20.32.50.80 | ||

adjusting vertical distance of ram | mm | 315 | |

Inclination of ram head | 0-8° | ||

Distance from front tool holding surface to column front | mm | 600 | |

Slotting cutter size(W*H) | mm | 25*40 | |

Work table diameter | mm | 630 | |

Distance from work table surface to below slide rack | mm | 490 | 510 |

Max. Longitudinal travel of work table(auto/manual) | mm | 480/620 | |

Cross traverse of work table(auto/manual) | mm | 480/560 | |

Feed range of work table in Longitudinal and cross direction | mm | 0.08-1.21 | |

Rotary feed range of work table | Deg. | 0.052-0.783 | |

Main motor power | KW | 4 | |

Main motor speed | rpm | 960 | |

Rapid traverse motor power | KW | 0.75(D) | |

Rapid traverse motor speed | rpm | 910(D) | |

Weight of mahine | Kg | 3500 | 3640 |

Overall dimension(L*W*H) | mm | 2290*1525*2285 | 2290*1525*2485 |

ITEM | UNIT | B50100 | B50125 | |

Max. slotting length | mm | 1000 | 1250 | |

Slotting speed | m/min | 4-25 | 4-30 | |

Return speed | m/min | 7-25 | 7-35 | |

Work table diameter | mm | 1250 | 1400 | |

Max. weight of work piece | Kg | 4000 | 4500 | |

Max. Longitudinal travel of work table(auto/manual) | mm | 1200 | 1400 | |

Cross traverse of work table(auto/manual) | mm | 1000 | 1120 | |

Rapid travel of work table longitudinal/cross | mm/min | 500 | ||

Distance from work table surface to below slide rack | mm | 1140 | 1650 | |

Distance from front tool holding surface to column front | mm | 1120 | 1600 | |

Feed range of work table in longitudinal and cross direction | mm | 0.2-5 | 0.2-3 | |

Rotary feed range of work table(ram move back and forth per time) | mm | 0.4-10 | 0.1-5 | |

Max. cutting force(speed 10-20m/min) | N | 24500 | ||

Main motor power | KW | 30 | 37 | |

Weight of machine | Kg | 22 | 26 | |

Overall dimension(L*W*H) | mm | 2290*1525*2285 | 2290*1525*2485 | |